Road Marking Materials

Thermoplastic Road Marking Paint

Thermoplastic Road Marking Paint

Thermoplastic Paint is made from petoleum resin, PE wax, pigment fillinngs. When heated, the powder form turned into molten liquid, and will form hard film after coated onto road surface. ACE hot melt paint has features of skid resistance, reflective, fast drying, anti-microcrack, etc.

Cold Solvent Road Marking Paint

Cold Solvent Road Marking Paint

Cold Solvent Road Marking Paint is consisted of modified acrylic resins, pigment filling and additive, generally used in city roads and common roads consisted of asphalt pavement and concrete road surface. Low cost and convenient operation.

Two-component Road Marking Paint

Two-component Road Marking Paint

Two-component road marking paint is composed of base materials and hardener. During construction, just need to mix the 2 components together with certain proportion. The hard paint film is quickly form due to chemical reaction, good internal structure, non-deformation by bad temperature.

Reflective Glass Beads

Reflective Glass Beads

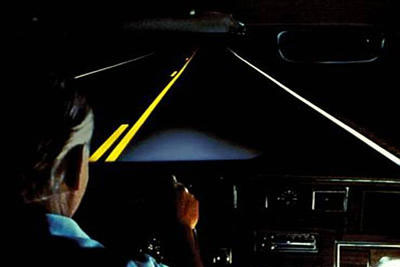

Reflective glass beads is added into road marking paints or coatings to improve the retro-reflection property of the road lines. Glass beads make the reflective marking lines reflex the headlights of the car back in parallel, so the driver could see the forward lane clearly and ensure the driving security.

Reflective Glass Beads

Reflective glass beads is used to improve the retro-reflection property of the road marking paint. When driving at night, the headlights flash on the marking line with glass beads which makes the headlights reflex back in parallel, so the driver could see the forward way clearly and the driving security is raised at night.

Reflective glass beads is used to improve the retro-reflection property of the road marking paint. When driving at night, the headlights flash on the marking line with glass beads which makes the headlights reflex back in parallel, so the driver could see the forward way clearly and the driving security is raised at night.

EMAIL: This email address is being protected from spambots. You need JavaScript enabled to view it.TEL: +86-371-55635088

Technical Data

| Exterior appearance | Transparent spheres, glabrous and round, no obvious bubbles and impurities |

| Roundness ratio | Roundness ratio≥80% (when 600<sphere diameter<850µm, roundness ratio≥75%) |

| Density | 2.4 - 2.6 g/cm3 |

| Refractive index | Nd≥1.50 |

| Glass element | Composed of soda-lime glass, content of SiO2 >68% |

Note:

In the road marking industry, a reasonable roundness ratio of reflective glass beads is more than 70 percent. But it is not the higher roundness ratio the better. Because, over-high spherical rate of glass beads will make the reflected light too strong, cause strong visual stimulation to the driver. Thus a small amount of irregular glass beads is required, to produce a diffuse reflection, making the reflected light soft.

Pictures

Enquiry Form

[Form Enquiry not found!]

Two-component Road Marking Paint

Two-component road marking paint is composed of base materials and hardener. During construction, just need to mix the base materials and hardener together with certain proportion. Due to chemical reaction, base materials and hardener quickly form hard paint film.

Two-component road marking paint is composed of base materials and hardener. During construction, just need to mix the base materials and hardener together with certain proportion. Due to chemical reaction, base materials and hardener quickly form hard paint film.

EMAIL: This email address is being protected from spambots. You need JavaScript enabled to view it.TEL: +86-371-55635088

Technical Data

| Binder/resin | 20.00 |

| Dispersing additive | 0.10 |

| Rheology additive | 0.10 |

| Pigment (TiO) | 10.00 |

| Fine filler (15 p:m) | 20.00 |

| Coarse filler (0.1 - 0.4 mm) | 25.00 |

| Premix beads | 25.00 |

Features

Use special screeding road marking machine or screed board to apply the lines. This paint has a thick coating. Compared with traditional thermoplastic paint, its advantages are as follow:

1. Good adhesion, hard coating, long service life even on busy traffic road.

2. Various construction methods, less requirement on construction equipment, easy construction.

3. Suitable for parking lines, pedestrian crossing, special lane and such kinds of city road markings.

Use special swing structure and structure road marking machine to finish construction work. Compared with traditional structure paint, this paint has following advantages:

1. Good cost performance. Its total cost is lower than that of thermoplastic marking.

2. Good adhesion of glass beads, excellent visibility in rainy day and at night.

3. Good rain dredge ability.

4. Hard paint film, good internal structure, non-deformation effected by temperature. And the swing structure marking can avoid damage to the marking caused by snow shovel.

Enquiry Form

[Form Enquiry not found!]

Cold Solvent Road Marking Paint

ACE Group's cold solvent road marking paints are made of high quality raw material, and its whole production processes are finished by completely automatic production line, absolutely avoid quality defects caused by artificial operation, such as large mixture ratio error, unstable quality, etc. Packaging: 25 kg, steel drum.

ACE Group's cold solvent road marking paints are made of high quality raw material, and its whole production processes are finished by completely automatic production line, absolutely avoid quality defects caused by artificial operation, such as large mixture ratio error, unstable quality, etc. Packaging: 25 kg, steel drum.

EMAIL: This email address is being protected from spambots. You need JavaScript enabled to view it.TEL: +86-371-55635088

Technical Data

| Physical Characteristics | Standard | Result | |

| State in container: | No agglomeration, crust, easy to stir uniformly | pass | |

| Density (g/cm3): | 1.2 min. | 1.42 | |

| Viscosity: (daubing 4 cups, s) | 100 min. | 145 | |

| Drying time of no sticking to wheel (minute) | 15 max. | 10 | |

| Covering Power: | White | 95 min. | 98 |

| Yellow | 80 min. | 85 | |

| Luminance factor: | White | 75 min. | 81 |

| Yellow | 45min. | 52 | |

| Adhesiveness (By circle method): | 4.0 max. | 2 | |

| Abrasion Resistance (mg, 200r/1000g reduce weight): | 40 max. | 23.60 | |

| Flexibility (mm): | 5.0 max. | 1.0 | |

| Solids content (%) | 60 min. | 69.9 | |

Features

1. ACE cold-sovlent road marking paint include two colors, white and yellow, is supplied ready for use and is suitable for application to bituminous and concrete roads.

2. It can be successfully applied to airless or air auxiliary spraying equipment.

3. The desired line width and flim thickness can be achieved by varying the spraying gun height, nozzle size, pump pressure and driving speed.

4. It can also be successfully applied with a brush or roller for smaller applications.

Pictures

Enquiry Form

[Form Enquiry not found!]

Thermoplastic Road Marking Paint

ACE Group owns automatic thermoplastic road marking paint production line, the annual production capacity of thermoplastic road marking paint reaches to 100,000 tons. ACE Thermoplastic Road Marking Paint include white and yellow, and have many features, such as skid resistance, reflective, fast drying, anti-microcrack, etc.

ACE Group owns automatic thermoplastic road marking paint production line, the annual production capacity of thermoplastic road marking paint reaches to 100,000 tons. ACE Thermoplastic Road Marking Paint include white and yellow, and have many features, such as skid resistance, reflective, fast drying, anti-microcrack, etc.

EMAIL: This email address is being protected from spambots. You need JavaScript enabled to view it.TEL: +86-371-55635088

Technical Data

| Physical Characteristics | Standard | Result | |

| Appearance Colour: | White/Yellow | White/Yellow | |

| Density (g/cm3): | 1.8 ~ 2.3 | 2.02 | |

| Softening Point (oC): | 90 ~ 125 | 103 | |

| Drying time of no sticking to wheel (minute) | 3 max. | 3 | |

| Luminance factor: | White | 75 min. | 83 |

| Yellow | 45min. | 51 | |

| Compression Strength(Mpa): | 12 min. | 18.10 | |

| Skid Resistance (BPN): | 50 min. | 55 | |

| Flow Resistance (%): | 35±10 | 38 | |

| Glass Beads Content (%w/w): | 18 ~ 25 | 22.6 | |

| Abrasion Resistance (mg 200r/1000g reduce weight): | 80 max. | 53.60 | |

| Flash Point (oC): | 230oC min. | 250 oC | |

Features

Adhesivity: Unique formulation ensures good adhesion with the road surface. Before the construction, apply some special primer produced by our company on the road (especially on the cement roadbed) which will make the paint adhesive with the road strongly.

Skid resistance: Anti-skid additive is contained which ensures the excellent levelling and skid resistance of the paint and maximally ensures the driving security.

Reflective ability: Sufficient volume of high quality coating type glass beads with stable refractive index are contained in the paint. Scientifically choose mixed glass beads with different particles according to the glass beads’ sedimentation rate in the paint to ensure the good reflective effect no matter the marking is new or old.

Fast drying: paints with different formulations are provided according to the temperature, humidity and road conditions in construction, which ensures the paint with excellent drying speed and good antifouling.

Stability: mixed with raw materials of excellent light and thermal stability. Anti-ultraviolet additive is added in the paint which is used in the strong sunlight areas to ensure the marking’s original color and luster for a long time.

Anti-microcrack: road marking’s microcrack is a big technical problem in the international road marking industry. After our long-term research, this problem has been solved completely by adding high temperature resistance lipid materials and functional structural materials.

Pictures

Enquiry Form

[Form Enquiry not found!]